Turbocharged Engines: Power, Efficiency, and How They Work

🚀 Turbocharged Engines: The Secret to Big Power in Small Packages

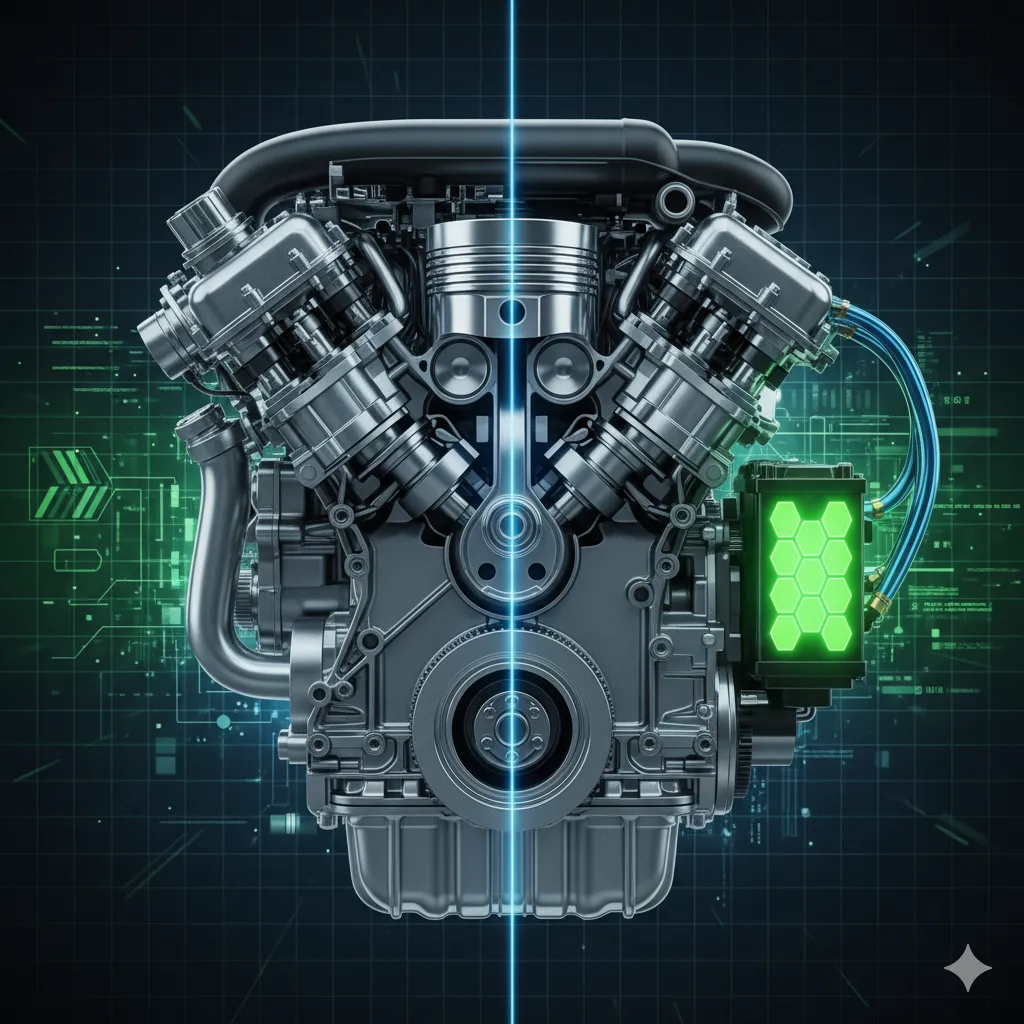

In today's automotive world, it seems like everything is getting smaller, yet more powerful. That little four-cylinder engine under the hood of your sleek new crossover? It might be punching above its weight thanks to a clever piece of engineering: the turbocharged engine. This technology is no longer just for high-performance sports cars; it’s now the go-to solution for manufacturers aiming to meet strict fuel efficiency and emissions standards without sacrificing horsepower.

But how do these miniature jet engines bolted to your exhaust manifold actually work? Is it magic, or just brilliant physics? Spoiler alert: it's the latter. This deep dive will break down the mechanics of turbocharged engines, explain their core components, detail the benefits, and give you the essential knowledge to keep your boosted ride running perfectly.

Understanding Forced Induction: The Core Concept

What is a Turbocharger?

At its heart, a turbocharger is a forced induction device that significantly increases the power output of an internal combustion engine.

In a standard, naturally aspirated engine, power is limited by the amount of air the cylinders can naturally draw in based on atmospheric pressure. A turbocharger bypasses this limitation by actively forcing more air—and therefore more oxygen—into the combustion chamber.

More air means you can burn more fuel, and burning more fuel equals more power from the same size engine. It's essentially the engine taking a deep, pressurized breath instead of a normal sip.

How a Turbocharger Works: The Brilliant Loop

The genius of the turbocharger lies in its ability to generate this power boost using energy that would otherwise be completely wasted: the engine's hot exhaust gases.

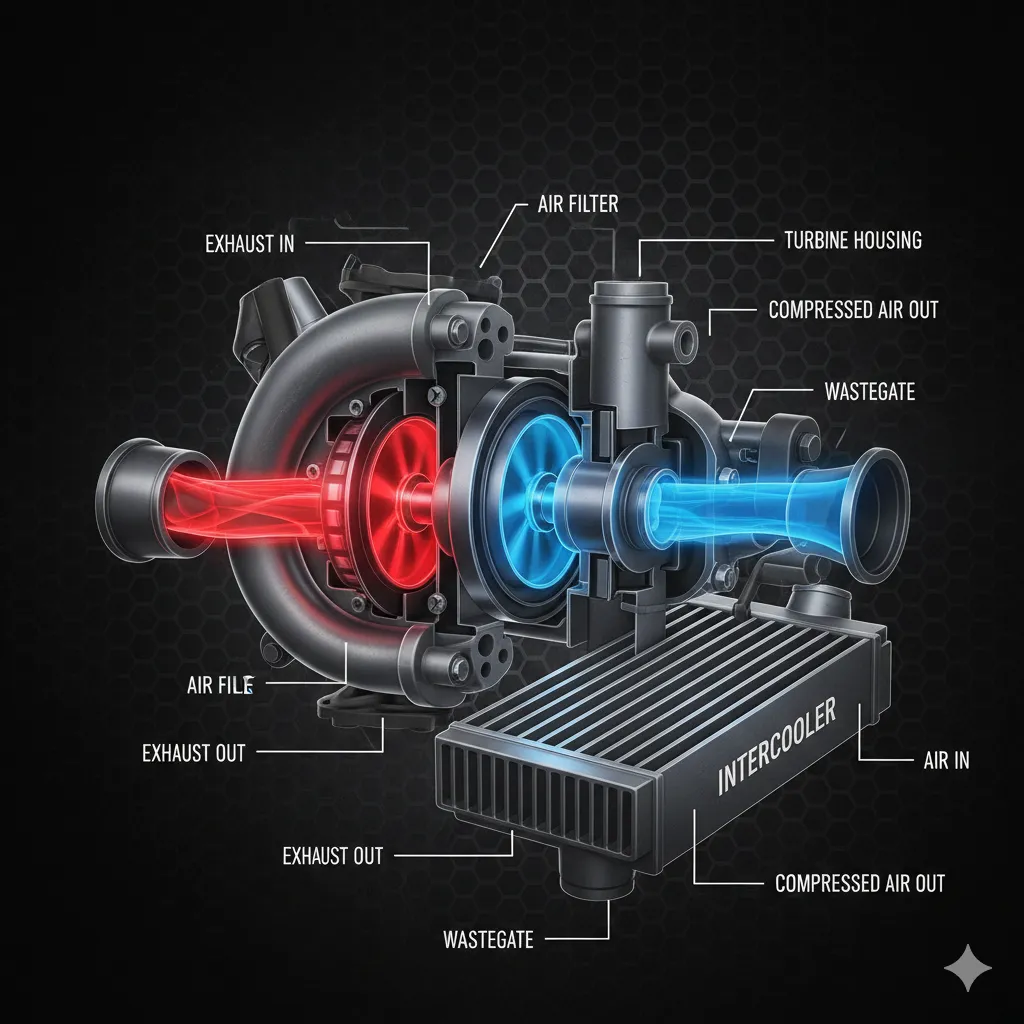

The turbocharger is a relatively simple device composed of two main sections connected by a shared shaft:

1. The Turbine Side (The Power Generator)

-

Turbine Wheel: Hot exhaust gas, expelled from the engine's cylinders, flows into the turbo's turbine housing. This high-pressure gas strikes the blades of the turbine wheel, causing it to spin at incredible speeds—often over 200,000 revolutions per minute (RPM)!

-

The Energy Recovery: This process reclaims kinetic energy from the exhaust stream to power the entire system.

2. The Compressor Side (The Air Booster)

-

Compressor Wheel: Since the turbine and compressor wheels are mounted on the same shaft, the spinning turbine causes the compressor wheel to spin as well.

-

Air Compression: The compressor wheel draws in cool, ambient air (filtered through the air intake) and rapidly compresses it. This compression is where the forced induction magic happens, creating "boost" pressure.

The Role of the Intercooler (Charge Air Cooler)

When air is compressed, it naturally heats up (thanks, physics!). Hot air is less dense than cool air, which defeats the turbo's purpose of getting more oxygen into the cylinder. This is where the intercooler steps in.

The compressed, hot air is routed through this component—which looks like a small radiator—where it is cooled before entering the engine's intake manifold. Cooler, denser air means more oxygen, which ultimately leads to a bigger, more efficient combustion event and the increased power you feel.

The Key Components of a Turbocharged System

A complete turbocharged engine system involves more than just the turbo unit itself:

-

Exhaust Manifold: Directs the hot exhaust gases from the cylinders into the turbine housing.

-

Wastegate: This is a control valve that diverts excess exhaust gas away from the turbine wheel when the engine reaches a pre-set maximum boost pressure. This prevents the turbo from spinning too fast, which would lead to engine damage.

-

Blow-Off Valve (or Diverter Valve): When the driver suddenly lifts off the accelerator, the throttle body closes, trapping high-pressure air in the intake. This valve releases that excess pressure to prevent a surge from slowing the compressor wheel, which helps maintain responsiveness.

Benefits and Trade-Offs of Turbocharged Engines

Why are manufacturers embracing turbocharged engines so widely?

✅ Turbo Benefits (The Upsides of Boost)

| Feature | Naturally Aspirated Engine | Turbocharged Engine |

| Power Output | Limited by atmospheric pressure. | Significantly boosted power for the size. |

| Fuel Efficiency | Often lower due to larger engine displacement needed for power. | Excellent, as smaller engines can be used (Engine Downsizing). |

| Altitude Performance | Power drops off as air thins out. | Maintains power output by forcing air in. |

| Engine Size | Larger displacement required for high power. | Smaller, lighter displacement engine achieves higher power. |

The main draw is engine downsizing. A small, fuel-efficient 1.5-liter four-cylinder turbo can now easily produce the power of an older, much larger 2.5-liter six-cylinder engine. You get the fuel economy of the smaller engine with the performance of the larger one.

🛑 The Trade-Off: Understanding Turbo Lag

One common critique of a turbocharged engine is "turbo lag." This is the brief, noticeable delay between the moment you press the accelerator and the moment the power surge kicks in.

-

What Causes It? At low engine RPMs, there isn't enough exhaust gas flow to rapidly spin the heavy turbine wheel. The turbo needs a moment for the exhaust flow to build up and get the turbine spinning fast enough to generate significant boost.

-

Modern Solutions: Advancements like twin-scroll turbochargers (which separate exhaust pulses) and variable geometry turbochargers (which adjust the turbine's shape) have drastically reduced or eliminated turbo lag in modern vehicles, making the power delivery almost instant and seamless.

Maintenance Tips for Your Turbocharged Engine

Turbochargers are incredibly durable, but they operate at extreme heat and speed, making proper maintenance paramount. If you own a vehicle with a forced induction system, keep these tips in mind:

1. Use High-Quality Engine Oil

The turbocharger's bearing system is lubricated by your engine oil. Because of the intense heat, the oil can "coke" or burn, forming deposits that damage the bearings. Always use the manufacturer-recommended high-quality (often synthetic) oil and adhere strictly to oil change intervals.

2. Warm-Up and Cool-Down

-

Start-Up: Avoid aggressive acceleration before the engine oil has reached operating temperature, which can take a few minutes.

-

Shut-Down: After a hard drive (like a long highway stint or mountain driving), let the engine idle for 30–60 seconds before shutting it off. This allows the turbo to cool down slightly and ensures the shaft bearings are properly lubricated as the turbo spools down.

3. Monitor Boost and Listen Closely

Keep an eye on your boost gauge if you have one. Any sudden, unexplained drops in boost pressure or a noticeable increase in whining or scraping noises could indicate a leaking hose, a wastegate issue, or bearing failure. Get it checked immediately.

Frequently Asked Questions (FAQs)

Q1: Is a turbocharged engine less reliable than a naturally aspirated engine?

Modern turbocharged engines are highly reliable due to better engineering, materials, and oil technology. However, their complexity and operation at higher heat mean they require more stringent and regular maintenance, especially using the correct oil, to maintain that reliability. Neglecting maintenance is the fastest way to cause a turbo failure.

Q2: Does a turbocharger hurt my engine's lifespan?

No, not if properly maintained. The engine itself is typically designed and built with stronger components (pistons, rods, heads) to handle the increased stress and pressure from the turbo. The key is maintenance; an unmaintained turbo can introduce contaminants and heat issues that will reduce engine lifespan.

Q3: What does "PSI of boost" mean?

PSI stands for "Pounds per Square Inch" and is the unit of pressure used to measure the amount of compressed air the turbocharger is forcing into the engine's intake manifold above normal atmospheric pressure (which is about 14.7 PSI at sea level). A typical factory turbo might run anywhere from 6 to 15 PSI of boost.

Conclusion: The Future is Boosted

Turbocharged engines represent a fantastic synergy of power and efficiency, turning waste energy into performance gains. By understanding the core mechanics of how a turbocharger works and committing to a diligent maintenance schedule, you can enjoy the exhilarating power and impressive fuel economy that modern forced induction technology delivers. These powerful, smaller engines are not just a passing trend—they are the current standard and will continue to dominate the combustion engine landscape for years to come.

e) External Links

-

For the history and technical details of the turbocharger: Wikipedia: Turbocharger

-

For general automotive maintenance and engine care tips: Edmunds: Car Maintenance

-

For a deeper dive into engine efficiency standards: Environmental Protection Agency (EPA): Light-Duty Vehicle Emission Standards